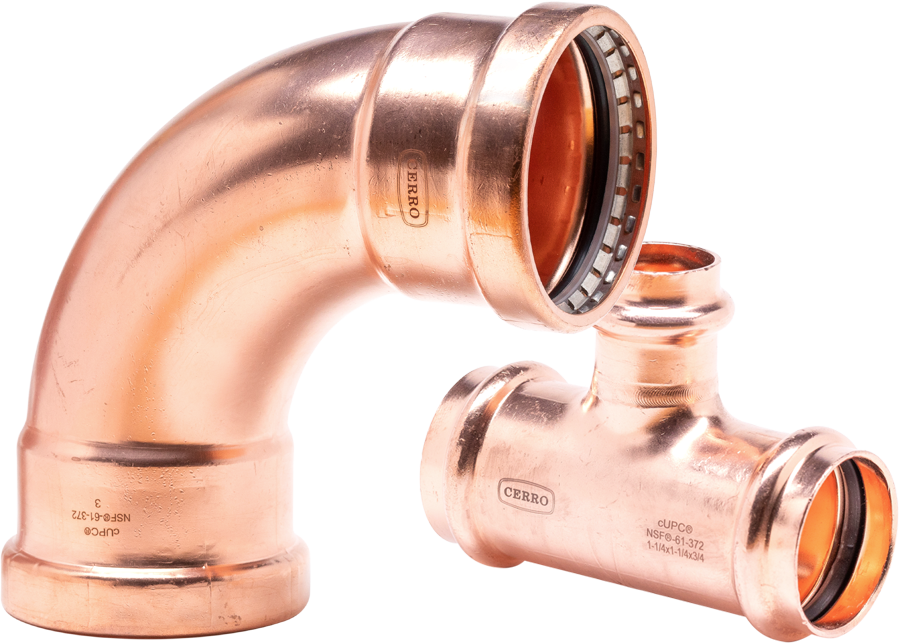

CerroPress® Press fittings drastically reduce installation time of connections by more than half when compared to traditional copper soldered fittings. Best of all, the quality of a press connection with CerroPress is consistent, repeatable and verifiable with the proper training.

CerroPress® Press fittings drastically reduce installation time of connections by more than half when compared to traditional copper soldered fittings. Best of all, the quality of a press connection with CerroPress is consistent, repeatable and verifiable with the proper training.

What makes our CerroPress copper press fittings for plumbing so easy to install?

No Special Jaws Required

CerroPress® fittings are compatible with most common industry standard professional press tools and jaws. For a list of compatible tools and jaws please see our CerroPress Installation Manual.

No Flame Required

CerroPress® press-to-connect fittings eliminate the open flames required to solder sweat-to-connect fittings and brazed joints. Unlike solder joints, press-to-connect fittings require no fire watch nor hot work permits, which helps improve the economy of choosing press fittings.

No flame press-to-connect technology helps prevent accidents which means a safer jobsite for Installers.

Field Lubrication of Sealing Element O-Ring Required

Using CerroPress means elimination of the extra step of field lubricating press fitting sealing element O-rings. CerroPress sealing element O-rings are pre-lubricated in the factory. Tubing will easily insert into CerroPress fittings without additional field applied lubrication. Field applied oil-based lubricant could damage and shorten the life of the sealing element O-Ring. CerroPress fittings can be used straight out of the bag with confidence.

No Worry

Our O-rings are designed with leak detection features so the installer can quickly identify un-pressed connections during water and air pressure tests.

For more information and installation instructions click on the QR Code. Or visit cerropress.com

Follow all additional manufacturer recommendations found on CerroPress.com.